Постоянная магнитная муфта с ограничением крутящего момента

1. В муфте с постоянными магнитами, ограничивающей крутящий момент, между ротором с постоянным магнитом и проводником имеется переменный воздушный зазор.

2. Постоянная магнитная муфта с ограничением крутящего момента позволяет добиться эффективного эффекта передачи, отсутствия вибрации и экономии энергии.

3. Постоянная магнитная муфта с ограничением крутящего момента имеет функцию защиты от перегрузки, которая автоматически сбрасывается после устранения проблемы.

- KUDOSWORLD

- КИТАЙ

- 6-8 РАБОЧИХ НЕДЕЛЬ

- 1000 КОМПЛЕКТОВ/ГОД

- Информация

- видео

- скачать

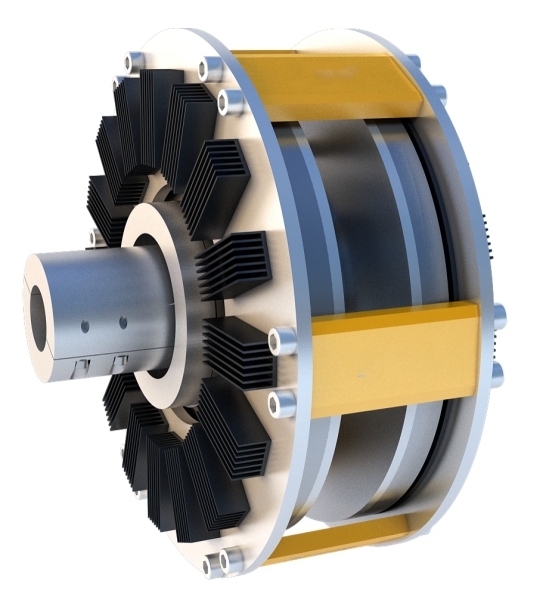

Product introduction of Torque Limiting Permanent Magnetic Coupling:

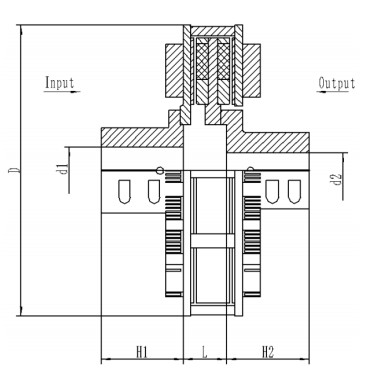

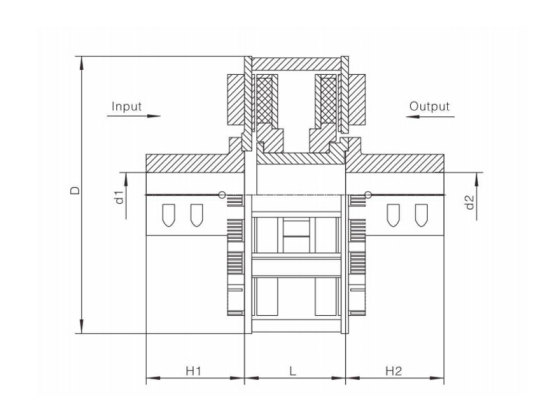

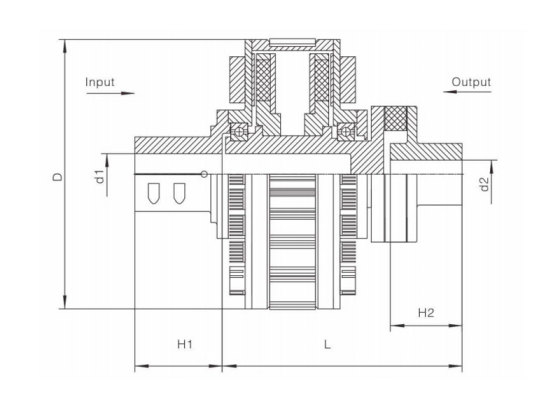

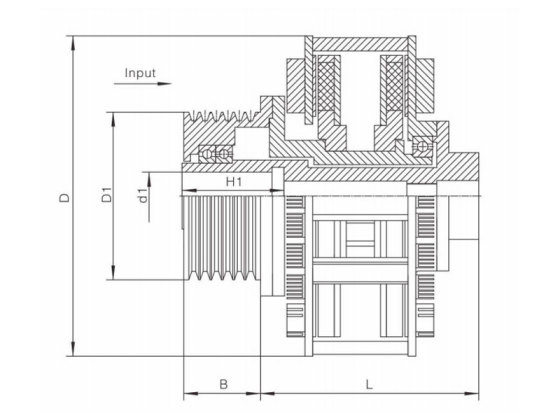

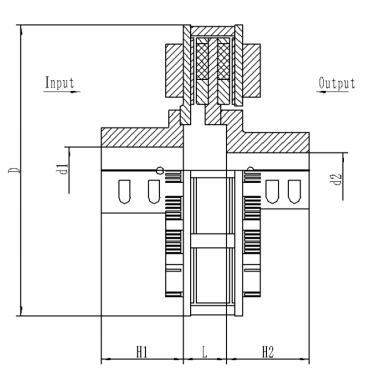

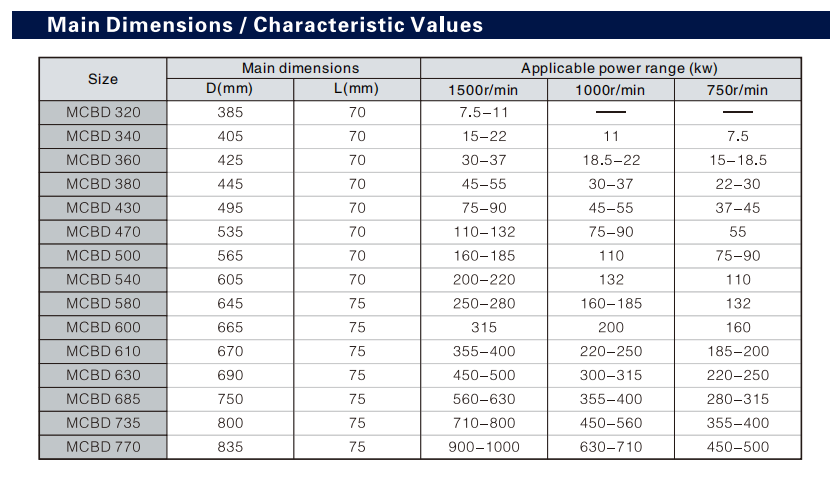

The Permanent Magnet Coupling is a device which transmits the torque from the motor to the load through the air gap between the conductor ring and the permanent magnet rotor. It can realize the transmission mode without mechanical connection between motor and load. Magnetic drive Couplings have a variety of different models to choose from, including various specifications of bore diameters, torque transmission ranges, etc. The torque transmission range of this Magnet Shaft Couplings ranges from a few N/m to several thousand N/m, which can meet the torque requirements of different transmission systems. The bore diameter of Permanent Magnetic Couplings can be customized according to different drive device requirements and there are usually a variety of available specifications. Our Magnetic Couplings are used in various transmission systems, including machine tools, printing machinery, textile machinery, packaging machinery, mixing machinery, and other fields. No matter what industry you are in, our product can meet any of your needs.

Classification:

Due to the different air gap adjustment methods, permanent magnetic devices are divided into 3 different types such as standard type, delayed type, torque-limited type, and speed-regulated type.

The standard type: The air gap length is not adjustable

The delayed type and the torque-limited type: The length of air gap can be adjusted to meet the requirements of different occasions.

The speed-regulated type: The adjustment range of air gap length is the largest. The speed can be adjusted by adjusting the air gap length. Equipped with air gap adjustment mechanism.

Similarities of the 3 types are that The magnetic circuit structure is basically the same, based on the standard type.

LMC Limited Torque Permanent Magnet Coupling

Applications

Magnet Shaft Couplings is suitable for on-site equipment with large axial displacement

Magnetic drive Couplings is suitable for equipment requiring soft start, unstable load and overload protection. For example elevator, crusher, belt conveyor, bucket wheel, etc.

Magnet Shaft Couplings can be used in machine tool transmission systems, such as CNC machine tools, lathes, milling machines, drilling machines, etc., to achieve high-precision transmission results and improve the processing accuracy and efficiency of machine tools.

Permanent Magnetic Couplings can be used in the transmission system of textile machinery, such as spinning machines, looms, winding machines, etc., to achieve high-speed and stable transmission effects and improve the production efficiency and quality of textiles.

Magnetic drive Couplings are used in the transmission system of packaging machinery, such as carton sealing machines, labeling machines, filling machines, etc., to achieve high-precision transmission and positioning, improving packaging efficiency and accuracy.

Product advantages of Torque Limiting Permanent Magnetic Coupling:

Permanent Magnetic Couplings use magnetic materials as transmission media, require no lubrication and maintenance, have a long service life and high reliability, and reduce the failure rate and maintenance costs of the transmission system.

Magnetic drive Couplings can be customized and designed according to different transmission requirements. They are suitable for various transmission systems and can meet the requirements of different working conditions and environments.

When the driving machine drives the conductor ring to rotate, it makes a circular motion of cutting magnetic force line relative to the permanent magnet rotor installed at the driven end, so that the conductor ring.

At the active end produces eddy current magnetic field, and interacts with the permanent magnet magnetic field at the driven end, so as to realize no contact between the active end and the driven end Torque transfer.

At rated load of Magnetic drive Couplings, the air gap between the permanent magnet rotor and the conductor ring is the smallest.

When the Magnet Shaft Couplings are overloaded or stuck, the air gap between the permanent magnet rotor and the conductor ring increases rapidly until it reaches the maximum air gap, and the speed of the permanent magnet rotor at the machine end decreases until it stops rotating, thereby overloading the motor protect.

Kudosworld is an industrial technology group with businesses all over the world. We provide a series of solutions, including advanced technology, manufacturing, products and precision services. Provide products and services for key markets such as new energy, oil and gas, mines, ports, steel, etc. We take Kudosworld (China) as the core of operation and management, rely on the technology of Kudosworld in Germany, and cooperate with global production bases for processing and manufacturing. Over the past decades, we have made contributions to the development and implementation of hundreds of projects where product quality, technological progressiveness and reliability are the prerequisites for success. From finding the best customer solution to complex project delivery, customer trust proves our experience, reliability and professionalism.